Aseptic processing has become a cornerstone of modern food preservation, and it’s particularly vital when it comes to tomato paste. This method ensures a safe, high-quality product with an extended shelf life, benefiting everyone from consumers and chefs to food businesses. Unlike traditional preservation techniques, aseptic processing focuses on eliminating all microorganisms, resulting in a product that doesn’t require refrigeration until opened. This significantly reduces waste and maintains the vibrant flavor and nutritional value of the tomatoes.

For those seeking consistent quality and reliability in their ingredients, Nature Valley UAE offers a range of high-quality aseptic tomato paste, perfect for both home and professional kitchens. This article will delve into the intricacies of aseptic processing, exploring its benefits, the production process, and why it’s the preferred choice for preserving the goodness of tomato paste.

Aseptic processing isn’t just about extending shelf life; it’s about providing a consistently safe and nutritious product. Traditional methods, like hot-packing or canning, rely on heat to kill microorganisms, but they can sometimes compromise flavor, color, and nutrient content. Aseptic processing, on the other hand, sterilizes the product and the packaging separately before combining them in a sterile environment. This allows for gentler processing, preserving more of the tomato’s natural characteristics.

Here’s how aseptic processing benefits different groups:

- Consumers: Enjoy convenient, ready-to-use tomato paste that remains fresh for extended periods, reducing food waste and saving time.

- Chefs: Rely on consistent quality and predictable results in their recipes, minimizing variability and ensuring superior taste.

- Food Businesses: Benefit from reduced storage costs, extended distribution ranges, and a reputation for delivering safe, high-quality products.

Throughout this article, we will explore the science behind aseptic processing, the step-by-step production process, and the regulatory standards that ensure its safety and effectiveness. We’ll also address common questions and concerns, helping you understand why aseptic tomato paste is a superior choice for both culinary applications and everyday use.

What is Aseptic Processing? A Deep Dive into the Fundamentals

Aseptic processing is a food preservation technique where the product is sterilized separately from its packaging. This stands in contrast to traditional methods like canning, where both the food and the container are heated together to achieve sterilization. The core principle of aseptic processing revolves around eliminating all viable microorganisms – bacteria, yeasts, molds, and spores – from the product and then maintaining that sterility during packaging and storage.

Let’s break down the key components:

- Sterilization of the Product: Typically achieved through Ultra-High Temperature (UHT) processing, which involves heating the tomato paste to a very high temperature (around 135-150°C or 275-302°F) for a very short duration (2-5 seconds). This rapidly heats and cools the product, minimizing thermal damage while effectively killing microorganisms. Other methods, like filtration, can also be employed.

- Sterilization of the Packaging: Packaging materials (often multilayered cartons, pouches, or cans) are sterilized using methods like steam sterilization, hydrogen peroxide treatment, or irradiation. This ensures that the packaging itself doesn’t introduce any contaminants into the product.

- Aseptic Filling & Sealing: The sterilized product is then filled into the sterilized packaging in a sterile environment, typically within a sealed chamber or room with highly filtered air. This is crucial – any exposure to non-sterile air can re-contaminate the product. The packaging is then hermetically sealed to prevent any further microbial ingress.

How does aseptic processing differ from other preservation techniques?

| Feature | Aseptic Processing | Canning | Pasteurization |

| Sterilization | Product & packaging sterilized separately | Product & packaging sterilized together | Reduces microbial load; doesn’t achieve sterility |

| Temperature | High (UHT) for short duration | High for longer duration | Lower temperatures |

| Shelf Life | Long (months or even years) | Moderate (months) | Short (days or weeks) |

| Flavor & Nutrient Retention | Excellent | Moderate | Best, but limited shelf life |

| Packaging | Aseptic cartons, pouches, cans | Metal cans, glass jars | Bottles, cartons |

The importance of eliminating microorganisms:

Microorganisms are the primary cause of food spoilage, leading to undesirable changes in flavor, texture, odor, and safety. By effectively eliminating these microorganisms, aseptic processing allows for the creation of a shelf-stable product that doesn’t require refrigeration until opened. This significantly extends the product’s usability, reduces food waste, and ensures that the consumer receives a safe and high-quality food product. The focus on complete sterility makes aseptic processing a cornerstone of modern food preservation technology.

The Science Behind Aseptic Packaging

Aseptic packaging isn’t simply about using sterile containers; it’s a sophisticated technology relying on specialized materials, rigorous sterilization methods, and crucial barrier properties to maintain product sterility throughout its shelf life. Let’s delve into the science behind it:

Packaging Materials:

Aseptic packaging commonly utilizes multilayered structures, typically composed of several layers of different materials. These layers are chosen for their specific functionalities:

- Polyethylene (PE): Provides a heat-sealable layer for creating airtight closures.

- Polypropylene (PP): Offers rigidity and resistance to high temperatures.

- Aluminum Foil: Acts as an excellent oxygen and light barrier, protecting the product from degradation.

- Paperboard: Provides structural support and printing surface for branding and product information.

- Ethylene Vinyl Alcohol (EVOH): Offers a superior barrier against oxygen, aroma, and flavor loss.

This combination of materials creates a package that is strong, durable, and highly protective. The specific composition of the layers can be tailored to the characteristics of the product being packaged – for example, tomato paste requires a particularly robust oxygen barrier.

Sterilization Methods:

Maintaining the sterility of the packaging is paramount. Several methods are employed:

- Steam Sterilization: Commonly used for metal cans and some rigid plastic containers. The packaging is exposed to high-pressure steam at temperatures exceeding 121°C (250°F) for a specific duration.

- Hydrogen Peroxide (H₂O₂) Sterilization: Widely used for multilayered cartons and pouches. The packaging material is sprayed with a dilute hydrogen peroxide solution, which acts as a powerful disinfectant. The residual hydrogen peroxide is then decomposed through a catalytic process.

- Electron Beam (E-Beam) Irradiation: Used less frequently but effective for certain plastics. Involves exposing the packaging to a beam of electrons, which disrupts the DNA of any microorganisms present.

- UV-C Radiation: Primarily used for surface sterilization and is often used in conjunction with other methods.

The chosen sterilization method depends on the type of packaging material and the desired level of sterility.

Barrier Properties:

Effective aseptic packaging must possess excellent barrier properties to prevent the ingress of microorganisms and protect the product from external factors:

- Oxygen Barrier: Crucial for preventing oxidation, which can lead to changes in color, flavor, and nutritional value. Aluminum foil and EVOH layers provide excellent oxygen protection.

- Light Barrier: Prevents photo-oxidation and degradation of light-sensitive components. Aluminum foil and pigmented layers offer effective light protection.

- Moisture Barrier: Prevents water vapor from entering or exiting the package, maintaining product consistency and preventing spoilage. Polypropylene and EVOH layers provide excellent moisture protection.

- Aroma Barrier: Prevents the loss of volatile aroma compounds, preserving the product’s flavor profile. EVOH layers are particularly effective in retaining aroma.

The effectiveness of these barrier properties is critical for ensuring the long shelf life and quality of aseptic packaged products. Rigorous testing is conducted to ensure that the packaging material meets strict standards for barrier performance.

Aseptic Processing vs. Canning: Key Differences

Both aseptic processing and canning are established methods for preserving food, but they differ significantly in their approach, resulting in distinct advantages and disadvantages. Traditional canning has been a mainstay of food preservation for centuries, while aseptic processing represents a more modern, technologically advanced technique. Here’s a detailed comparison, with a particular focus on the impact on flavor and nutritional value:

| Feature | Aseptic Processing | Canning |

| Sterilization Method | Product & packaging sterilized separately before combining in a sterile environment | Product and packaging sterilized together during heating |

| Heating Temperature | High temperature, short duration (UHT – Ultra-High Temperature) | Lower temperature, long duration |

| Packaging | Aseptic cartons, pouches, cans | Metal cans, glass jars |

| Processing Time | Relatively fast | Relatively slow |

| Flavor & Aroma Retention | Excellent – minimal thermal degradation due to short heating time | Moderate – longer heating time can lead to flavor and aroma loss |

| Nutrient Retention | Excellent – less thermal damage preserves vitamins and minerals | Moderate – some nutrient loss due to prolonged heating |

| Color Retention | Excellent – maintains vibrant color | Moderate – color may fade or change during heating |

| Texture | Excellent – maintains product texture | Moderate – texture may become softer during heating |

| Shelf Life | Long (months to years) | Moderate (months) |

| Refrigeration after Opening | Required | Required |

| Cost | Generally higher initial investment | Generally lower initial investment |

A Deeper Look at Flavor & Nutritional Value:

The key difference lies in the heating process. Canning relies on prolonged exposure to high temperatures to kill microorganisms, which inevitably leads to some degradation of heat-sensitive vitamins (like Vitamin C and B vitamins), minerals, and volatile aroma compounds. This can result in a product with a slightly altered flavor profile and reduced nutritional value.

Aseptic processing, on the other hand, utilizes UHT processing, which involves very high temperatures for only a few seconds. While the temperature is higher, the short duration minimizes thermal damage to the product’s delicate components. This results in a product that more closely resembles the fresh original in terms of flavor, color, texture, and nutritional value.

Advantages of Aseptic Processing:

- Superior Flavor & Aroma: Maintains a more natural taste profile.

- Higher Nutritional Value: Preserves more vitamins and minerals.

- Extended Shelf Life: Allows for longer storage times without refrigeration.

- Reduced Waste: Longer shelf life reduces the risk of spoilage.

Disadvantages of Aseptic Processing:

- Higher Initial Investment: Requires specialized equipment and packaging materials.

- Potential for Package Defect Issues: Strict quality control is essential to prevent contamination.

In conclusion:

While canning remains a viable preservation method, aseptic processing offers significant advantages in terms of flavor, nutritional value, and shelf life. The modern technology and precise control involved in aseptic processing make it the preferred choice for preserving the quality and integrity of sensitive food products like tomato paste.

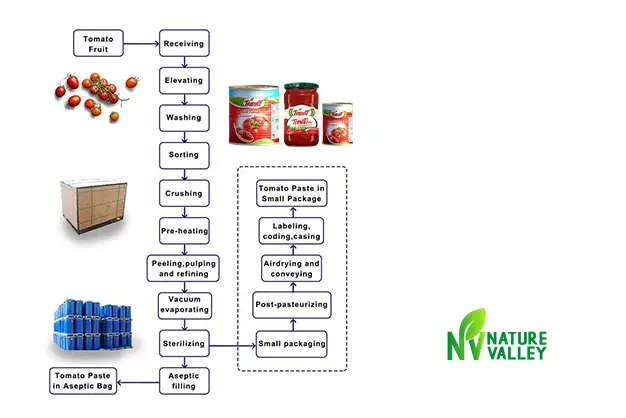

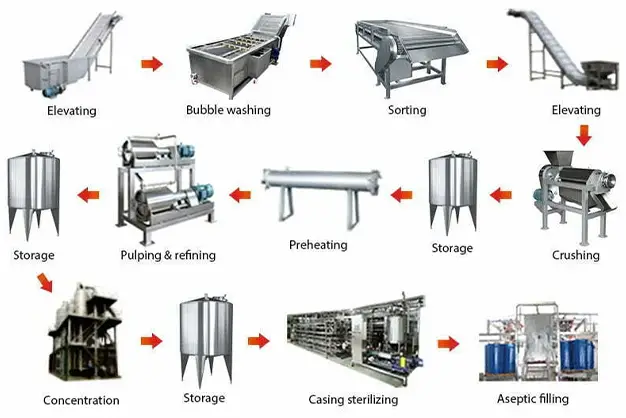

Aseptic Tomato Paste Production: A Step-by-Step Guide

Producing aseptic tomato paste is a meticulous process requiring precise control at every stage to ensure sterility and maintain product quality. Here’s a detailed breakdown, from raw material selection to final packaging, with a focus on aseptic techniques:

- Raw Material Selection & Receiving (Pre-Processing):

- Tomato Variety: High-solids, red-ripened tomatoes with a low incidence of defects are crucial. Variety selection impacts final paste quality.

- Quality Control: Incoming tomatoes are rigorously inspected for ripeness, color, defects (bruising, mold), and pesticide residues. Rejected tomatoes are discarded.

- Cleaning: Tomatoes are thoroughly washed with potable water (often with added sanitizers) to remove dirt, debris, and potential microbial contaminants.

- Crushing & Pre-Heating:

- Crushing: Tomatoes are mechanically crushed to break down cell walls, facilitating juice extraction.

- Hot Break: The crushed tomatoes are heated to approximately 85-90°C (185-194°F) to deactivate enzymes that cause undesirable changes in color and viscosity. This is not a sterilization step but prepares the juice for subsequent processing.

- Pulp Extraction: The hot-broken tomato pulp is screened to remove skins, seeds, and other insoluble materials.

- Evaporation & Concentration:

- Multi-Stage Evaporation: The tomato juice is concentrated using multi-stage vacuum evaporators. This reduces water content and increases the solids content (typically to 28-32%). Vacuum evaporation minimizes thermal damage.

- Steam Sterilization of Evaporator: The evaporators are continuously steam-sterilized to maintain a sterile environment.

- Sterilization (UHT Processing):

- Plate Heat Exchanger (PHE): The concentrated tomato paste is pumped through a PHE, where it’s rapidly heated to UHT temperatures (135-150°C / 275-302°F) for a very short duration (2-5 seconds). This eliminates all microorganisms.

- Homogenization (Optional): After UHT treatment, the paste can be homogenized to improve texture and stability. This involves forcing the paste through a small space under high pressure.

- Cooling: The UHT-treated paste is rapidly cooled to approximately 60-80°C (140-176°F) to prevent re-contamination and maintain quality.

- Aseptic Filling & Packaging:

- Sterilization of Packaging Materials: Aseptic cartons, pouches, or cans are thoroughly sterilized using steam sterilization, hydrogen peroxide treatment, or electron beam irradiation before filling.

- Aseptic Filling: The sterilized paste is filled into the sterilized packaging within a sterile environment (aseptic chamber) to prevent contamination.

- Hermetic Sealing: The packaging is immediately hermetically sealed to prevent ingress of microorganisms.

- Quality Control Checks: Filled packages are inspected for leaks, proper sealing, and any signs of contamination.

- Post-Packaging Handling:

- Cooling: Packages are further cooled to room temperature.

- Coding & Labeling: Packages are coded with batch numbers, production dates, and expiration dates.

- Storage & Distribution: Packages are stored and distributed under controlled conditions to maintain quality and prevent damage.

Throughout this entire process, stringent hygiene protocols, regular cleaning and disinfection of equipment, and continuous monitoring of temperatures and pressures are essential to maintain sterility and ensure the production of a safe, high-quality aseptic tomato paste. Each stage is critically evaluated to minimize risks of contamination and maximize product shelf life.

Raw Material Selection & Preparation for Aseptic Processing

The success of aseptic tomato paste production hinges on starting with high-quality raw materials and meticulously preparing them for processing. Compromises at this stage can significantly impact the final product’s flavor, color, viscosity, and, most importantly, its sterility and shelf life.

1. Tomato Variety Selection:

- Solids Content: Varieties with a naturally high solids content (e.g., Roma, Heinz 1350) are preferred. Higher solids reduce water activity, making the paste less susceptible to microbial growth.

- Red Ripeness: Fully ripe, red tomatoes with consistent color development are crucial for optimal flavor and lycopene content. Underripe or overripe tomatoes can impart undesirable flavors and reduce quality.

- Disease Resistance: Choosing disease-resistant varieties minimizes defects and reduces the risk of contamination.

- Cultivation Practices: Sourcing tomatoes from reputable growers employing good agricultural practices (GAP) ensures minimal pesticide residues and consistent quality.

2. Receiving & Inspection:

- Quality Control: Incoming tomatoes are rigorously inspected for ripeness, color, size, defects (bruising, mold, insect damage), and foreign materials.

- Rejection Criteria: Tomatoes exhibiting significant defects, mold growth, or excessive bruising are rejected to prevent contamination.

- Temperature Control: Maintaining appropriate receiving temperatures helps preserve tomato quality and prevent pre-growth of microorganisms.

3. Washing & Sanitization:

- Removal of Debris: Thorough washing with potable water removes dirt, soil, and other extraneous materials.

- Sanitization: Washing with a food-grade sanitizer (e.g., chlorine dioxide, peracetic acid) reduces the microbial load on the tomato surface.

- Water Quality: Utilizing high-quality, potable water is essential to avoid introducing contaminants.

- Brushing (Optional): Gentle brushing can help remove stubborn dirt and debris, but it must be done carefully to avoid damaging the tomatoes.

4. Crushing & Hot Break:

- Gentle Crushing: Tomatoes are mechanically crushed to break down cell walls, facilitating juice extraction. Over-aggressive crushing can release undesirable enzymes and particles.

- Hot Break: Heating the crushed tomatoes to 85-90°C (185-194°F) inactivates enzymes that cause undesirable changes in color, viscosity, and flavor during storage.

- Pulp Extraction: Screening the hot-broken tomato pulp removes skins, seeds, and other insoluble materials, improving the final product’s texture and clarity.

- Preventing Contamination: Maintaining hygienic conditions throughout the crushing and hot break process is critical to prevent microbial contamination.

By focusing on meticulous raw material selection and preparation, processors can establish a foundation for a successful aseptic tomato paste production process, ensuring a safe, high-quality product with extended shelf life. This initial stage sets the tone for all subsequent operations, minimizing risks and maximizing the final product’s potential.

Sterilization & Homogenization Processes

Sterilization and homogenization are two critical steps in aseptic tomato paste production, directly impacting product safety, stability, and quality. Sterilization eliminates all viable microorganisms, ensuring a shelf-stable product, while homogenization improves texture and consistency.

1. Sterilization (UHT Processing):

- Principle: Ultra-High Temperature (UHT) processing involves heating the tomato paste to a very high temperature (typically 135-150°C / 275-302°F) for a very short duration (2-5 seconds). This rapid heating effectively destroys all microorganisms, including spores, and inactivates enzymes.

- Plate Heat Exchanger (PHE): The most common method for UHT processing involves using a Plate Heat Exchanger. The tomato paste is pumped between thin plates, allowing for rapid and uniform heating and cooling.

- Indirect vs. Direct UHT:

- Indirect UHT: The paste is heated by passing it over heated plates. This is the most common method, as it avoids direct contact between the paste and heating medium.

- Direct UHT: The paste is injected into steam under pressure. This method is less common due to the potential for flavor changes.

- Holding Time: Maintaining the UHT temperature for the appropriate holding time is crucial to ensure complete sterilization. The specific holding time depends on the temperature and the characteristics of the paste.

- Cooling: Immediately after UHT treatment, the paste is rapidly cooled to approximately 60-80°C (140-176°F) to prevent re-contamination and maintain quality. Rapid cooling is essential.

- Aseptic Packaging: The UHT-treated paste must be packaged aseptically immediately to prevent re-contamination.

2. Homogenization (Optional):

- Principle: Homogenization involves forcing the UHT-treated paste through a small space under high pressure (typically 15-25 MPa / 2175-3625 psi). This reduces the size of fat globules and other particles, resulting in a smoother, more stable product.

- Single-Stage vs. Two-Stage Homogenization:

- Single-Stage Homogenization: The paste is passed through the homogenizer once. This is sufficient for many applications.

- Two-Stage Homogenization: The paste is passed through the homogenizer twice, resulting in a finer particle size and improved stability.

- Benefits of Homogenization:

- Improved Texture: Creates a smoother, more consistent texture.

- Enhanced Stability: Prevents separation of solids and liquids during storage.

- Reduced Sedimentation: Minimizes the formation of sediment at the bottom of the package.

- Increased Viscosity: Can slightly increase the viscosity of the paste.

- Considerations:

- Energy Consumption: Homogenization requires significant energy input.

- Potential for Flavor Changes: Homogenization can sometimes slightly alter the flavor profile of the paste.

Both sterilization and homogenization are critical steps in ensuring a safe, high-quality, and stable aseptic tomato paste product. Careful control of processing parameters is essential to maximize benefits and minimize potential drawbacks.

The Importance of Aseptic Packaging in Maintaining Food Safety

Aseptic packaging is not merely a convenience feature; it’s the cornerstone of food safety in aseptic processing, particularly crucial for tomato paste. This technology significantly reduces the risk of contamination, minimizes spoilage, and extends the product’s shelf life, protecting consumers and reducing food waste.

Preventing Contamination: The Multi-Barrier Approach:

The core principle of aseptic packaging revolves around creating a multi-barrier system to prevent the ingress of microorganisms. This system includes:

- Sterile Product: The tomato paste itself is sterilized using Ultra-High Temperature (UHT) processing, eliminating all viable microorganisms.

- Sterile Packaging Materials: Packaging materials (cartons, pouches, cans) are thoroughly sterilized using methods like steam sterilization, hydrogen peroxide treatment, or electron beam irradiation before filling.

- Sterile Environment: The filling and sealing process occurs within a meticulously controlled sterile environment (aseptic chamber) with highly filtered air, preventing re-contamination.

- Hermetic Sealing: The packaging is immediately hermetically sealed, creating an airtight barrier that prevents the entry of microorganisms and oxygen.

This multi-barrier approach dramatically reduces the likelihood of contamination from bacteria, yeasts, molds, and spores, ensuring a safe and shelf-stable product.

Reducing Spoilage & Extending Shelf Life:

By preventing contamination, aseptic packaging effectively minimizes spoilage, extending the shelf life of tomato paste significantly compared to other preservation methods. This offers several benefits:

- Reduced Food Waste: Longer shelf life reduces the risk of spoilage and waste, benefiting both consumers and the environment.

- Lower Storage Costs: Longer shelf life allows for more efficient storage and distribution, reducing costs.

- Wider Distribution Range: Aseptic packaging enables the distribution of tomato paste to wider geographical areas without compromising safety or quality.

- Elimination of Refrigeration (until opened): Aseptic packaging eliminates the need for refrigeration during storage and transport, further reducing costs and complexity.

Relevant Food Safety Standards:

Aseptic packaging and processing are subject to rigorous food safety standards to ensure consumer protection. Key standards include:

- HACCP (Hazard Analysis and Critical Control Points): A systematic preventive approach to food safety that identifies, evaluates, and controls hazards critical to the safety of the product. Aseptic processing requires a comprehensive HACCP plan covering all stages of production, from raw material selection to packaging.

- ISO 22000: An internationally recognized food safety management system that specifies requirements for a food safety management system, including prerequisite programs, HACCP principles, and traceability.

- GMP (Good Manufacturing Practices): A set of guidelines outlining the minimum standards for manufacturing practices, ensuring that products are consistently produced and controlled according to quality standards.

- FDA Regulations (in the USA): The Food and Drug Administration sets specific regulations for aseptic processing and packaging of low-acid canned foods, including requirements for sterilization validation and container integrity.

- European Food Safety Authority (EFSA) Regulations: EFSA sets similar stringent standards for food safety in Europe.

Compliance with these standards is essential for ensuring the safety and quality of aseptic tomato paste and maintaining consumer trust. Regular audits and inspections are conducted to verify compliance and ensure adherence to best practices.

In conclusion, aseptic packaging is a critical component of food safety, providing a multi-barrier system that prevents contamination, reduces spoilage, extends shelf life, and protects consumers. Adherence to stringent food safety standards is essential for ensuring the quality and integrity of aseptic tomato paste.

Shelf Life & Quality Retention: Benefits of Aseptic Tomato Paste

Aseptic processing offers significant advantages in extending the shelf life of tomato paste while preserving its quality attributes – color, flavor, vitamins, and nutrients – compared to traditional preservation methods. This makes aseptic tomato paste a superior choice for both consumers and food businesses.

Extended Shelf Life – A Comparative Look:

| Preservation Method | Typical Shelf Life |

| Canning | 6-12 months |

| Pasteurization | Few weeks |

| Refrigeration | Few days |

| Aseptic Processing | 6-12 months (unopened) or even longer |

The extended shelf life of aseptic tomato paste is primarily due to the complete elimination of microorganisms through UHT processing and the multi-barrier protection provided by aseptic packaging. This eliminates the need for refrigeration until the package is opened, offering convenience and reducing storage costs.

Impact on Color Retention:

Traditional canning often leads to some degradation of color due to prolonged heat exposure and oxidation. Aseptic processing, with its rapid heating and cooling and oxygen-impermeable packaging, significantly minimizes color loss. The lycopene content (responsible for the red color and antioxidant properties) is also better preserved. Aseptic tomato paste typically maintains a vibrant red color throughout its extended shelf life.

Impact on Flavor Retention:

Prolonged heat exposure and oxygen exposure can also negatively impact flavor in traditional methods. Aseptic processing minimizes these effects, resulting in a tomato paste with a fresher, more natural flavor profile. While some subtle flavor changes may occur over time, they are significantly less pronounced compared to other methods. The volatile compounds responsible for the characteristic tomato flavor are better preserved.

Impact on Vitamin & Nutrient Retention:

Aseptic processing has a positive impact on vitamin and nutrient retention compared to traditional methods. Here’s a breakdown:

- Vitamin C: While some Vitamin C loss occurs during heating, aseptic processing minimizes this loss compared to prolonged heating in canning.

- Lycopene: Lycopene, a powerful antioxidant, is relatively stable during UHT processing and is well-preserved in aseptic packaging.

- Beta-Carotene: Beta-carotene levels are also better retained compared to traditional methods.

- Other Nutrients: Other essential nutrients, such as potassium and fiber, are largely unaffected by UHT processing.

Food Safety and Quality Interplay:

The extended shelf life achieved through aseptic processing is directly linked to enhanced food safety. By eliminating microorganisms, the risk of spoilage and foodborne illness is significantly reduced. This allows for longer storage times without compromising the quality or safety of the product.

Factors Influencing Shelf Life:

- Packaging Integrity: Any compromise to the packaging (leaks, damage) can reduce the shelf life.

- Storage Conditions: Storing aseptic tomato paste at room temperature in a dry, dark place is optimal.

- Batch Quality: Variations in raw material quality can slightly impact shelf life.

In conclusion, aseptic processing offers a significant advantage in extending the shelf life of tomato paste while preserving its color, flavor, and nutritional value, ultimately ensuring a safe, high-quality product for consumers. The combination of rapid heating, sterile packaging, and multi-barrier protection makes it the superior choice for long-term storage and distribution.

Aseptic Tomato Paste Applications: For Consumers, Chefs & Food Businesses

Aseptic tomato paste is a versatile ingredient with a wide range of applications, catering to the needs of consumers, professional chefs, and large-scale food businesses. Its convenience, long shelf life, and consistent quality make it a valuable asset in various culinary and industrial settings.

For Consumers: Home Cooking & Convenience:

- Pasta Sauces: Aseptic tomato paste forms the foundation of countless homemade pasta sauces, offering a rich, concentrated tomato flavor.

- Soups & Stews: Adds depth and complexity to soups, stews, and chili recipes.

- Curries & Braises: Provides a vibrant tomato base for Indian curries and slow-cooked braises.

- Pizza Sauce: A convenient starting point for making authentic pizza sauce.

- Marinades & Rubs: Adds a tangy tomato flavor to marinades and rubs for meats and vegetables.

- Tomato Soup: A concentrated base for quick and easy homemade tomato soup.

- Convenience & Reduced Waste: Aseptic packaging allows for using only the required amount, minimizing waste and reducing food spoilage.

For Chefs: Professional Culinary Applications:

- Sauce Development: Provides a consistent, high-quality base for creating a wide variety of sauces, from classic tomato sauces to complex reductions.

- Braises & Stews: Adds depth and richness to braised meats, stews, and soups, ensuring consistent flavor profiles.

- Pizza & Pasta: A reliable ingredient for making authentic Italian pizza sauce and pasta sauces, offering consistent quality and flavor.

- Tomato Concentrates & Purees: Can be used as a base for making tomato concentrates and purees, offering control over consistency and flavor.

- Sous Vide Cooking: Ideal for adding tomato flavor to sous vide dishes, providing consistent results.

- Reduced Preparation Time: Consistent quality reduces preparation time and ensures predictable results in a professional kitchen.

For Food Businesses: Industrial Applications & Large-Scale Production:

- Pasta Sauce Production: A key ingredient in large-scale pasta sauce manufacturing, ensuring consistent quality and flavor.

- Canned Soup Production: Provides a concentrated tomato base for various canned soup varieties.

- Pizza Sauce & Toppings: Used in the production of pizza sauce and pizza toppings, ensuring consistent quality and flavor.

- Ketchup & Tomato Puree Production: A vital ingredient in the manufacturing of ketchup, tomato puree, and other tomato-based products.

- Spice Paste & Seasoning Production: Used in the production of spice pastes, seasoning blends, and marinades.

- Ready Meals & Convenience Foods: Incorporated into ready meals, sauces, and other convenience foods, ensuring consistent quality and long shelf life.

- Cost-Effective Ingredient: A consistent, reliable, and cost-effective ingredient for large-scale food production.

- Inventory Management: Long shelf life simplifies inventory management and reduces waste.

In conclusion, aseptic tomato paste is a versatile ingredient with a wide range of applications, catering to the diverse needs of consumers, professional chefs, and large-scale food businesses. Its convenience, long shelf life, consistent quality, and cost-effectiveness make it a valuable asset in various culinary and industrial settings.

Benefits for Consumers: Convenience & Quality

For individual consumers, aseptic tomato paste offers a compelling combination of convenience, consistent quality, and nutritional value, alongside the significant benefit of reduced food waste. These factors contribute to a more efficient and enjoyable cooking experience.

Convenience: A Kitchen Staple Ready When You Are:

- No Refrigeration Required (until opened): Aseptic packaging eliminates the need for refrigeration, freeing up valuable fridge space and making it a convenient pantry staple.

- Long Shelf Life: The extended shelf life (6-12 months or longer) means you can always have tomato paste on hand, eliminating last-minute trips to the grocery store.

- Easy to Store: Aseptic packages are compact and easy to store in a pantry or cupboard.

- Portion Control: Easily use only the required amount of paste, eliminating the need to use up an entire can at once.

- Reduced Cooking Time: A concentrated base for sauces, soups, and stews simplifies cooking and reduces preparation time.

Nutritional Value: Preserving the Goodness of Tomatoes:

- Lycopene Retention: Aseptic processing helps preserve lycopene, a powerful antioxidant with numerous health benefits.

- Vitamin C Retention: While some Vitamin C loss occurs during processing, aseptic processing minimizes this loss compared to other methods.

- Essential Nutrients: Provides essential nutrients like potassium and fiber.

- Healthful Ingredient: Adds a healthful tomato base to a variety of dishes.

Reduced Food Waste: Saving Money & the Environment:

- Eliminates Spoilage: Long shelf life significantly reduces the risk of spoilage, saving you money and reducing food waste.

- Use Only What You Need: The ability to use only the required amount eliminates the need to discard unused paste.

- Sustainable Choice: Reducing food waste contributes to a more sustainable lifestyle.

- Cost-Effective: Less waste translates to cost savings in the long run.

In conclusion, aseptic tomato paste offers a convenient, nutritious, and sustainable choice for individual consumers. Its long shelf life, convenient storage, and ability to reduce food waste make it a valuable addition to any kitchen, simplifying cooking and contributing to a more efficient and environmentally friendly lifestyle.

Benefits for Chefs: Consistency & Reliability

For professional chefs, maintaining consistent quality and predictable results are paramount. Aseptic tomato paste provides a reliable foundation for sauce development, braises, and numerous other culinary applications, offering significant advantages over traditional methods.

Consistent Quality: A Stable Base for Creative Cooking:

- Uniform Flavor Profile: Aseptic processing ensures a consistent flavor profile batch-to-batch, eliminating variability that can impact sauce development.

- Consistent Color & Texture: Provides a consistent color and texture, simplifying recipe development and ensuring predictable results.

- High-Quality Ingredient: Starts with high-quality tomatoes and preserves their natural flavor and color.

- Reduced Recipe Adjustments: Minimizes the need for recipe adjustments due to inconsistencies in ingredient quality.

Predictable Results: Confidence in Every Dish:

- Reliable Performance: Provides reliable performance in a variety of applications, from classic tomato sauces to complex reductions.

- Simplified Recipe Scaling: Makes it easier to scale recipes up or down without compromising flavor or quality.

- Consistent Cooking Times: Provides consistent cooking times, simplifying kitchen operations and ensuring predictable results.

- Reduced Risk of Errors: Minimizes the risk of errors due to inconsistencies in ingredient quality.

Extended Usability: Efficiency & Cost Savings:

- Long Shelf Life: Long shelf life reduces the need for frequent inventory replenishment, simplifying kitchen operations.

- Reduced Waste: Long shelf life minimizes waste due to spoilage, reducing costs and improving efficiency.

- Convenient Storage: Easy to store and use, simplifying kitchen operations and reducing preparation time.

- Consistent Supply: Ensures a consistent supply of high-quality tomato paste, eliminating disruptions to kitchen operations.

In conclusion, aseptic tomato paste provides chefs with the consistency, reliability, and extended usability they need to create exceptional dishes. Its consistent quality, predictable results, and long shelf life make it an indispensable ingredient in any professional kitchen.

Regulatory Aspects & Standards for Aseptic Processing

Aseptic processing is a highly regulated area of food production, demanding strict adherence to specific food safety regulations and standards to ensure consumer protection. Compliance with these regulations is essential for manufacturers seeking to produce and distribute aseptic products.

Key Food Safety Regulations:

- FDA Regulations (USA): The U.S. Food and Drug Administration (FDA) has specific regulations for low-acid canned foods (LACF), including stringent requirements for aseptic processing and packaging. 21 CFR Part 113 outlines the Current Good Manufacturing Practice (CGMP) regulations for LACF. This includes requirements for thermal processing validation, container integrity, and HACCP plan implementation.

- European Food Safety Authority (EFSA) Regulations: EFSA sets similar stringent standards for food safety in Europe. Regulation (EC) No 2073/2005 on microbiological criteria for foodstuffs addresses aspects of aseptic processing and packaging.

- HACCP (Hazard Analysis and Critical Control Points): A systematic preventive approach to food safety is required for all aseptic processing facilities. A comprehensive HACCP plan must identify, evaluate, and control hazards critical to the safety of the product, from raw material sourcing to packaging.

- GMP (Good Manufacturing Practices): Adherence to GMP regulations is essential for ensuring that products are consistently produced and controlled according to quality standards. This includes requirements for facility sanitation, equipment maintenance, and personnel training.

Certifications & Compliance Requirements:

- ISO 22000: An internationally recognized food safety management system that specifies requirements for a food safety management system, including prerequisite programs, HACCP principles, and traceability. Obtaining ISO 22000 certification demonstrates a commitment to food safety.

- BRCGS (Brand Reputation Compliance Global Standards): A leading global food safety and quality certification program. Obtaining BRCGS certification demonstrates a commitment to food safety and quality.

- FSSC 22000: Another globally recognized food safety certification scheme.

- Thermal Processing Validation: Independent validation of the thermal processing system is required to ensure that it effectively eliminates microorganisms.

- Container Integrity Testing: Regular testing of container integrity is required to ensure that the packaging effectively prevents the entry of microorganisms.

- Record Keeping: Detailed record keeping is required to demonstrate compliance with all relevant regulations.

- Regular Audits & Inspections: Food processing facilities are subject to regular audits and inspections by regulatory agencies to verify compliance with all relevant regulations.

- Personnel Training: All personnel involved in aseptic processing must be properly trained on food safety procedures.

- Traceability: A robust traceability system is required to track products from raw material sourcing to distribution.

Challenges & Future Trends:

- Increasing Regulatory Scrutiny: Regulatory agencies are continuously increasing scrutiny of food safety practices.

- Advanced Technologies: The adoption of advanced technologies, such as real-time monitoring and data analytics, is becoming increasingly important for ensuring food safety.

- Sustainable Packaging: The demand for sustainable packaging solutions is increasing.

- Harmonization of Regulations: Efforts are ongoing to harmonize regulations globally to facilitate international trade.

In conclusion, adhering to strict food safety regulations and obtaining relevant certifications are essential for manufacturers seeking to produce and distribute aseptic products. Continuous improvement and adoption of advanced technologies are crucial for ensuring food safety and meeting evolving regulatory requirements.

The Future of Aseptic Processing in the Food Industry

Aseptic processing is undergoing a period of significant innovation, driven by consumer demand for safer, more sustainable, and higher-quality food products. Emerging technologies and trends are reshaping the industry, promising increased efficiency, reduced environmental impact, and enhanced product characteristics.

1. Sustainable Packaging Solutions:

- Bio-based Polymers: Replacing traditional plastic packaging with bio-based polymers derived from renewable resources, such as corn starch or sugarcane, reduces reliance on fossil fuels and minimizes environmental impact.

- Recyclable & Compostable Materials: Developing packaging materials that are easily recyclable or compostable reduces waste and promotes a circular economy.

- Reduced Packaging Weight & Volume: Optimizing packaging design to reduce weight and volume minimizes transportation costs and carbon emissions.

- Mono-Material Packaging: Utilizing single-polymer packaging simplifies recycling processes and improves recyclability rates.

- Plant-Based Coatings: Replacing traditional plastic coatings with plant-based alternatives reduces reliance on fossil fuels and enhances biodegradability.

2. Innovative Sterilization Methods:

- High-Pressure Processing (HPP): Utilizing high pressure to inactivate microorganisms without the use of heat, preserving the flavor, color, and nutritional value of food products.

- Pulsed Electric Field (PEF) Technology: Utilizing pulsed electric fields to disrupt the cell membranes of microorganisms, offering a gentler sterilization method compared to traditional heat treatment.

- UV-C Irradiation: Utilizing UV-C light to inactivate microorganisms on food surfaces and packaging materials, offering a non-thermal sterilization method.

- Cold Plasma Technology: Utilizing cold plasma to inactivate microorganisms and decontaminate food surfaces, offering a non-thermal sterilization method.

- Microfiltration & Ultrafiltration: Utilizing membrane filtration to remove microorganisms and particulates from food products, offering a gentle sterilization method.

3. Advanced Monitoring & Control Systems:

- Real-Time Monitoring of Sterilization Processes: Utilizing sensors and data analytics to monitor sterilization processes in real-time, ensuring consistent product quality and safety.

- Predictive Modeling & Artificial Intelligence (AI): Utilizing predictive modeling and AI to optimize sterilization processes, reduce waste, and improve efficiency.

- Blockchain Technology for Traceability: Utilizing blockchain technology to track products from raw material sourcing to distribution, ensuring transparency and accountability.

- Digital Twins for Process Optimization: Creating digital twins of aseptic processing facilities to simulate and optimize processes, reduce costs, and improve efficiency.

- Automated Quality Control Systems: Utilizing automated quality control systems to detect defects and ensure consistent product quality.

4. Minimally Invasive Processing Techniques:

- Aseptic Filling of Complex Products: Developing aseptic filling techniques for complex products, such as soups, sauces, and stews, that preserve the texture, flavor, and nutritional value of the product.

- Gentle Mixing & Homogenization Techniques: Utilizing gentle mixing and homogenization techniques to preserve the structure and texture of food products.

- Reduced Heat Exposure: Developing processing techniques that minimize heat exposure to preserve the flavor, color, and nutritional value of food products.

5. Personalized & Customized Aseptic Packaging:

- On-Demand Aseptic Packaging: Developing on-demand aseptic packaging solutions that allow for personalized and customized products.

- Smart Packaging: Utilizing smart packaging technologies that provide information about product freshness, safety, and origin.

- Active Packaging: Utilizing active packaging technologies that extend product shelf life and enhance food safety.

In conclusion, the future of aseptic processing is characterized by a focus on sustainability, innovation, and personalization. Emerging technologies and trends are reshaping the industry, promising increased efficiency, reduced environmental impact, and enhanced product characteristics. The adoption of these technologies will be crucial for meeting the evolving demands of consumers and ensuring the long-term success of the aseptic processing industry.

Troubleshooting Common Issues in Aseptic Tomato Paste Production

Aseptic tomato paste production, while highly controlled, is not immune to potential issues. Addressing problems promptly and effectively is crucial for maintaining product quality, safety, and minimizing financial losses. Here’s a breakdown of common problems, their causes, and potential solutions.

- Packaging Defects:

- Problem: Leaks, pinholes, improper sealing, package deformation.

- Causes: Damaged packaging materials, insufficient sealing temperature, improper machine settings, contamination of sealing surfaces, air entrapment.

- Solutions:

- Inspect packaging materials for damage before use.

- Verify and calibrate sealing machine temperature and pressure.

- Ensure sealing surfaces are clean and free of debris.

- Optimize packaging material selection for product compatibility.

- Implement a quality control check for seal integrity after filling.

- Consider headspace control to minimize air entrapment.

- Contamination (Microbiological or Foreign Material):

- Problem: Microbial growth (spoilage, off-flavors), presence of foreign objects (metal, plastic, glass).

- Causes: Insufficient sterilization, compromised packaging integrity, inadequate cleaning and sanitation procedures, equipment failure.

- Solutions:

- Re-validate the sterilization process to ensure effective microbial inactivation.

- Thoroughly clean and sanitize all equipment and surfaces according to established protocols.

- Implement a robust foreign material detection system (metal detectors, X-ray inspection).

- Regularly inspect equipment for damage or wear that could compromise sterility.

- Implement a strict personnel hygiene program.

- Flavor Changes (Off-Flavors, Burnt Taste, Metallic Taste):

- Problem: Unpleasant or undesirable flavors developing in the finished product.

- Causes:

- Overheating during processing: Can lead to Maillard reactions and burnt flavors.

- Metal corrosion: Interaction between tomato paste and corroded equipment can impart a metallic taste.

- Lipoxygenase activity: Enzyme activity can lead to off-flavors during storage.

- Contamination with mold or yeast: Can lead to off-flavors and spoilage.

- Packaging material interaction: Some packaging materials can impart off-flavors.

- Solutions:

- Optimize processing temperatures and times to minimize overheating.

- Use corrosion-resistant equipment (stainless steel 316L is preferred).

- Inactivate lipoxygenase enzymes before processing (blanching or heat treatment).

- Ensure proper cleaning and sanitation of all equipment to prevent mold and yeast growth.

- Select packaging materials that are compatible with tomato paste.

- Viscosity Issues (Too Thick, Too Thin):

- Problem: Paste is either too thick to pump or too thin to maintain desired consistency.

- Causes:

- Variations in tomato solids content: Affects viscosity.

- Improper heat treatment: Can affect pectin structure.

- Enzyme degradation: Can break down pectin.

- Storage conditions: Affect pectin structure.

- Solutions:

- Monitor tomato solids content and adjust processing parameters accordingly.

- Optimize heat treatment to maintain pectin structure.

- Inactivate enzymes that degrade pectin before processing.

- Control storage temperature and humidity.

- Sedimentation or Phase Separation:

- Problem: Separation of liquid and solid phases in the paste.

- Causes:

- Improper homogenization: Insufficient particle size reduction.

- Storage conditions: Temperature fluctuations can promote sedimentation.

- Enzyme activity: Can break down pectin and destabilize the paste.

- Solutions:

- Optimize homogenization parameters to achieve adequate particle size reduction.

- Control storage temperature and humidity.

- Inactivate enzymes that destabilize the paste before processing.

Preventative Measures (General):

- Robust Quality Control System: Implement a comprehensive quality control system at all stages of production.

- Regular Equipment Maintenance: Conduct regular equipment maintenance to ensure optimal performance.

- Personnel Training: Provide thorough personnel training on aseptic processing procedures.

- Traceability System: Implement a traceability system to track products from raw material sourcing to distribution.

- Documentation: Maintain detailed records of all processing parameters.

By proactively addressing potential problems and implementing preventative measures, manufacturers can ensure the production of safe, high-quality, and consistent aseptic tomato paste.

Frequently Asked Questions (FAQs) about Aseptic Tomato Paste

This section addresses common questions about aseptic tomato paste, covering production, safety, storage, and quality.

1. What exactly is aseptic tomato paste?

Aseptic tomato paste is a product that has been commercially sterilized after being packaged in a sterile container. This differs from traditional canning, where the product is sterilized in the container. Both the paste and the packaging are sterilized separately, then combined in a sterile environment.

2. How does aseptic processing differ from traditional canning?

| Feature | Aseptic Processing | Traditional Canning |

| Sterilization Timing | Product sterilized after packaging | Product sterilized in the container |

| Temperature | Typically higher temperatures for shorter times (UHT) | Lower temperatures for longer times |

| Packaging | Requires specialized, sterile packaging materials | Uses traditional cans or jars |

| Product Characteristics | Generally better preservation of flavor and nutrients | Can experience some loss of flavor and nutrients |

3. Is aseptic tomato paste safe?

Yes, aseptic tomato paste is considered very safe. The high-temperature sterilization process effectively eliminates harmful microorganisms and spores. The sterile packaging prevents re-contamination.

4. What is UHT processing?

UHT (Ultra-High Temperature) processing involves heating the tomato paste to a very high temperature (typically 135-150°C / 275-302°F) for a very short duration (2-5 seconds). This rapidly destroys all microorganisms and inactivates enzymes.

5. Does aseptic processing affect the nutritional value of tomato paste?

While some minor nutrient loss may occur, aseptic processing generally results in better preservation of nutrients compared to traditional canning due to the shorter processing times and rapid cooling. Lycopene, a beneficial antioxidant, is particularly well-preserved.

6. How long can aseptic tomato paste be stored?

Unopened aseptic tomato paste can typically be stored for 6-12 months or even longer at room temperature. Once opened, it should be refrigerated and used within a few days.

7. What does “aseptic” mean in the context of packaging?

“Aseptic” packaging refers to packaging materials that have been thoroughly sterilized before filling with the product. This ensures that the packaging itself does not introduce any microorganisms into the paste.

8. What types of packaging are commonly used for aseptic tomato paste?

Common packaging types include aseptic cartons, pouches, and metal cans with a special aseptic lining.

9. Why does aseptic tomato paste sometimes have a slightly cooked or caramelized flavor?

The high-temperature processing can sometimes result in a slightly cooked or caramelized flavor. This is generally not a quality defect and does not affect the safety of the product.

10. Is aseptic tomato paste suitable for all culinary applications?

Yes, aseptic tomato paste is suitable for a wide range of culinary applications, including sauces, soups, stews, and marinades.

11. What is the role of homogenization in aseptic tomato paste production?

Homogenization reduces the particle size of the tomato solids, creating a smoother texture and preventing sedimentation during storage.

12. Can I freeze aseptic tomato paste after opening?

Yes, you can freeze aseptic tomato paste after opening. However, it may affect the texture slightly. It’s best to use it as soon as possible after thawing.

13. Is aseptic tomato paste more expensive than traditional canned tomato paste?

Generally, aseptic tomato paste is slightly more expensive due to the specialized equipment and packaging required.

This FAQ section provides answers to common questions, offering consumers and food professionals valuable information about aseptic tomato paste.

14. What is the difference between pasteurized and aseptic tomato paste?

While both pasteurization and aseptic processing aim to preserve tomato paste, they employ significantly different methods resulting in distinct differences in shelf life, quality, and safety characteristics.

Pasteurization:

- Processing Method: Pasteurization involves heating the tomato paste to a relatively low temperature (typically 85-95°C / 185-203°F) for a moderate amount of time (a few minutes). This process aims to reduce the number of viable microorganisms, but it does not eliminate all of them, particularly heat-resistant spores.

- Packaging: The tomato paste is packaged before or immediately after pasteurization. The packaging itself is not necessarily sterile.

- Shelf Life: Pasteurized tomato paste typically has a shelf life of a few weeks or months, and requires refrigeration to slow down microbial growth.

- Quality Impact: Pasteurization can result in some loss of flavor and nutrients due to the moderate heat exposure. Texture can also be affected.

- Microbiological Safety: Relies on refrigeration to inhibit the growth of remaining microorganisms. Not considered a shelf-stable product without refrigeration.

Aseptic Processing:

- Processing Method: Aseptic processing involves heating the tomato paste to a very high temperature (Ultra-High Temperature – UHT, typically 135-150°C / 275-302°F) for a very short time (2-5 seconds). This process sterilizes the paste, eliminating virtually all viable microorganisms and spores.

- Packaging: The paste and the packaging are sterilized separately and then combined in a sterile environment. This is crucial to prevent re-contamination.

- Shelf Life: Aseptic tomato paste has a long shelf life (6-12 months or even longer) without refrigeration until opened.

- Quality Impact: While some minor nutrient loss may occur, aseptic processing generally results in better preservation of flavor and nutrients compared to pasteurization due to the shorter processing times and rapid cooling.

- Microbiological Safety: Considered a shelf-stable product because the paste is commercially sterile and the packaging prevents re-contamination.

Here’s a table summarizing the key differences:

| Feature | Pasteurized Tomato Paste | Aseptic Tomato Paste |

| Temperature | 85-95°C (185-203°F) | 135-150°C (275-302°F) |

| Processing Time | Minutes | Seconds |

| Sterilization | No complete sterilization | Complete sterilization |

| Packaging | Before/after pasteurization, not necessarily sterile | Sterile packaging in a sterile environment |

| Shelf Life | Weeks/months, requires refrigeration | 6-12+ months, no refrigeration needed |

| Microbiological Safety | Relies on refrigeration | Commercially sterile |

| Quality Impact | Some loss of flavor/nutrients | Better preservation of flavor/nutrients |

In conclusion, aseptic processing provides a significantly higher level of preservation and microbiological safety compared to pasteurization, resulting in a longer shelf life and better overall quality. While pasteurization is a viable method for short-term preservation, aseptic processing is the preferred method for producing a shelf-stable tomato paste that can be stored at room temperature.

15. Is aseptic tomato paste as nutritious as fresh tomatoes?

Determining whether aseptic tomato paste is “as nutritious” as fresh tomatoes is complex. Fresh tomatoes undoubtedly offer peak nutritional value immediately after harvest. However, factors like storage duration, transport distance, and handling can significantly diminish their nutrient content. Aseptic tomato paste, while processed, often retains more nutrients than fresh tomatoes after a period of time, and frequently outperforms other preservation methods in nutrient retention.

Nutrient Content of Fresh Tomatoes (at peak ripeness):

Fresh tomatoes are excellent sources of:

- Lycopene: A powerful antioxidant linked to reduced risk of certain cancers and heart disease.

- Vitamin C: An essential vitamin for immune function and antioxidant protection.

- Vitamin K: Important for blood clotting and bone health.

- Potassium: An electrolyte essential for heart health and muscle function.

- Fiber: Important for digestive health.

Nutrient Retention During Processing Methods:

| Preservation Method | Lycopene Retention | Vitamin C Retention | Potassium Retention | Other Nutrients |

| Fresh Tomatoes (Immediate Consumption) | 100% (baseline) | 100% (baseline) | 100% (baseline) | 100% (baseline) |

| Refrigerated Fresh Tomatoes (7 Days) | 80-90% | 60-70% | 80-90% | Variable |

| Canning | 50-70% | 20-40% | 40-60% | Moderate loss |

| Pasteurization | 60-80% | 30-50% | 50-70% | Moderate loss |

| Aseptic Processing | 80-90% | 50-70% | 70-85% | Relatively good |

Aseptic Processing & Nutrient Retention: Key Factors:

- Rapid Heating & Cooling: The short processing time minimizes heat exposure, reducing nutrient degradation.

- Sterile Environment: Prevents nutrient loss due to microbial activity.

- Packaging Protection: Protects nutrients from light and oxygen, preventing oxidation.

- Lycopene Bioavailability: Interestingly, processing tomatoes actually increases the bioavailability of lycopene, making it easier for the body to absorb. This is because heat breaks down cell walls, releasing more lycopene.

Specific Nutrient Breakdown in Aseptic Processing:

- Lycopene: Aseptic processing generally retains 80-90% of lycopene, and often enhances its bioavailability.

- Vitamin C: Aseptic processing retains 50-70% of Vitamin C, which is sensitive to heat and oxygen.

- Potassium: Aseptic processing retains 70-85% of Potassium, as it’s relatively stable during processing.

- Fiber: Fiber content remains largely unchanged during aseptic processing.

Comparison to Fresh Tomatoes:

- Immediately after harvest: Fresh tomatoes have superior nutrient content.

- After a few days of storage: Aseptic tomato paste often surpasses fresh tomatoes in nutrient retention, particularly for lycopene.

- Long-term storage: Aseptic tomato paste provides a consistent and reliable source of nutrients throughout its shelf life, while fresh tomatoes degrade rapidly.

Conclusion:

While fresh tomatoes offer peak nutritional value immediately after harvest, aseptic tomato paste is a highly nutritious option, especially when considering storage duration and long-term availability. Its rapid processing and sterile packaging help preserve a significant amount of vitamins and nutrients, often exceeding the nutrient content of fresh tomatoes after a few days of storage. Aseptic processing provides a convenient and consistent source of beneficial compounds, making it a valuable addition to a healthy diet.

16. What are the signs of spoilage in aseptic tomato paste?

Aseptic tomato paste is designed for long-term storage, but despite stringent processing, spoilage can occasionally occur due to compromised packaging or improper storage. Identifying the signs of spoilage is crucial to prevent foodborne illness. Here’s a breakdown of what to look for:

- Package Swelling or Bulging:

- Significance: This is a critical indicator of spoilage. Swelling indicates gas production inside the package, usually due to microbial activity. Do not consume the product.

- Appearance: The package will appear abnormally puffed or rounded. It may be difficult to press the sides inward.

- Leaks or Damage to Packaging:

- Significance: Compromised packaging allows microorganisms to enter, leading to spoilage.

- Appearance: Visible punctures, tears, or corrosion on the package. Even small holes can allow contamination.

- Discoloration:

- Significance: Changes in color can indicate microbial growth or chemical reactions.

- Appearance:

- Mold Growth: Visible fuzzy patches of white, green, or black mold. Do not consume.

- Darkening or Brown Spots: While some slight darkening is normal with long-term storage, significant discoloration warrants caution.

- Unusual Color Shifts: Any noticeable change from the typical vibrant red color.

- Unusual Odor:

- Significance: Off-odors are a strong indicator of spoilage.

- Appearance:

- Sour or Fermented Smell: Indicates bacterial activity.

- Yeasty or Musty Smell: Indicates mold growth.

- Off-putting or Chemical Smell: Indicates contamination or chemical reactions.

- Altered Texture or Consistency:

- Significance: Changes in texture can indicate microbial growth or enzyme activity.

- Appearance:

- Slimy Texture: Indicates bacterial growth.

- Foamy Appearance: Indicates gas production.

- Grainy or Separated Texture: Indicates protein degradation.

- Abnormal Taste:

- Significance: Only test a very small amount if the product appears otherwise normal. A bad taste is a clear indicator of spoilage.

- Appearance: Sour, bitter, or off-flavor.

Important Safety Notes:

- Do not consume: If any of these signs of spoilage are present, do not consume the product.

- Discard immediately: Properly dispose of the spoiled product to prevent contamination.

- Do not taste: Avoid tasting potentially spoiled food, as it could lead to foodborne illness.

- Store properly: Follow storage instructions to minimize the risk of spoilage.

By carefully inspecting aseptic tomato paste for these signs of spoilage, you can protect yourself and your family from foodborne illness.

Buy High-Quality Aseptic Tomato Paste from Nature Valley UAE

At Nature Valley UAE, we are committed to providing premium quality food products that are both delicious and nutritious. Our aseptic tomato paste is carefully sourced and processed to ensure exceptional flavor, consistent quality, and long-lasting shelf life.

We understand the importance of using reliable ingredients in your culinary creations. That’s why we utilize state-of-the-art aseptic processing technology to preserve the natural goodness of our tomatoes, delivering a product that’s perfect for sauces, soups, stews, and more.

Benefits of choosing Nature Valley UAE Aseptic Tomato Paste:

- Superior Quality Tomatoes: Sourced from the finest farms.

- Aseptic Processing: Ensures long-lasting freshness without compromising flavor.

- Consistent Flavor & Texture: Perfect results every time.

- Convenient & Long Shelf Life: No refrigeration needed until opened.

- Ideal for Commercial & Home Use: Versatile for various culinary applications.

Don’t settle for anything less than the best!

Visit naturevalleyuae.com today to browse our selection of high-quality aseptic tomato paste and place your order. We offer fast delivery throughout the UAE and exceptional customer service.

Order Now and Experience the Nature Valley Difference!